Digital signage for manufacturing is perhaps one of the least considered applications of the technology as a whole.

This does not mean, however, that the use of digital signage within this industry is any less impactful than some of its more familiar environments like retail.

From reinforcing key safety information to displaying monthly targets, here we compile the best uses of digital signage for factories…

To learn more, visit our dedicated digital signage for manufacturing page.

1. Reinforce Safety Information

Undoubtedly, the highest priority for those who work and operate in the manufacturing industry is safety. The reason being is that not only do employers want to protect their workers, but it costs them between £1,500-£100,000 depending on the severity of the injury. With this in mind, it is clear why those within the industry are always looking for new innovative ways to reduce the risk of workplace injuries.

Fortunately, the key elements of digital signage – repetitive and engaging content – can be utilised to help reinforce safety information. A well-placed screen combined with rotating safety information will guarantee that all employees are reminded of the safety precautions in place. Safety videos can also be incorporated to ensure the proper use of equipment and what to do in emergencies.

Considering ROI in the manufacturing industry is measured by improvements in safety, digital signage for factories can certainly be amongst more traditional safety precautions.

2. Increase Productivity

Making sure that staff are aware of key production metrics (e.g. production totals, inventory levels, and quality control) ensures that production operates efficiently and to a high standard. This information is usually distributed through daily or weekly meetings, alongside being accessible from stock-level management software on a computer. The time taken to meet on a daily or weekly basis, as well as repeatedly having to check stock levels, however, will eventually add up and lower overall productivity.

The installation of digital signage can either entirely replace or supplement these two methods. Team meetings can now be tailored more towards team-building and increasing morale, subsequently encouraging an increase in productivity. Integrating with stock-level management software is also possible within digital signage, allowing for live stock updates on the materials listed in the software. Once again, this reduces the time spent obtaining this information, increasing overall productivity. Screens can equally be used to motivate employees by creatively displaying manufacturing targets. Visualising how close you are to weekly or monthly targets can be the catalyst needed to stimulate that final push towards the end goal. Incorporating this with business achievements, such as best salesperson of the month, or highest customer satisfaction, will certainly improve productivity.

3. Effectively Respond to Accidents and Hazards

With warehouses spanning thousands of square feet with multiple levels, a rather common issue is internal communication. When there are breakdowns or delays in communication, it can be potentially dangerous, for example, when operating heavy machinery or when there’s a fire. As such, It’s imperative that when an accident or hazard does occur that all staff is made aware and react with the appropriate response.

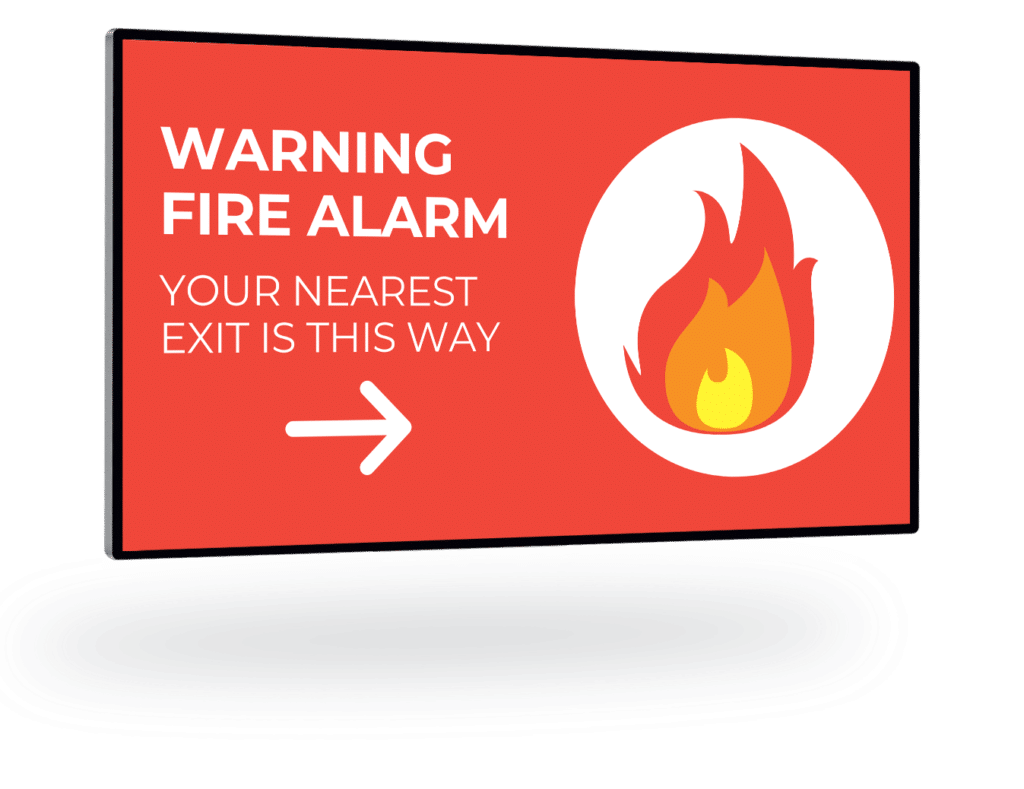

Once again, the manufacturing industry can exploit the fundamental features of digital signage. Being able to centrally control all the screens in your network, as well as transmit updates quickly, will mean accidents and hazards are communicated and dealt with effectively. Digital screens are also an ideal medium to display directions for where to go in these cases of an emergency. They can not only mirror static signage but, in case a regular exit becomes dangerous to use, they can also be used to redirect people to use the safest route out of the building.

4. Control Your Network

As already mentioned, the sheer size of some factories and warehouses can make it difficult to communicate. Those who want to combat this through the use of digital signage will require multiple screens strategically placed around the workplace. Up until a few years ago, this would then have meant that changing the content on the screen would have been rather time-consuming, as you would have to go round to each screen and upload the new content. This is perhaps why the benefits of digital signage for factories are only just being utilised.

Nowadays, as technology continues to move towards cloud-based solutions, you no longer have to manually change the content on each screen separately. Instead, content can be changed from one central dashboard anywhere in the world. Consequently, as your screen network begins to grow, or those who already have multinational locations, can now effortlessly control what is playing on each and every screen.

The level of control you have even extends to exactly when content is present on your screen. This is particularly useful when you want to plan and schedule content ahead of time. Perhaps an important member of staff or external guest is visiting and you want to coordinate specific content to play when they arrive. For example, triggering content as part of a manufacturing plant tour. Alternatively, it could be as simple as creating and applying motivational content to be displayed at the end of a shift or the month, spurring a final push towards monthly targets.

If you have any questions related to digital signage for factories, speak to an expert today. Call one of our friendly team on 02380 981110 or Email info@troudigital.com for a no-obligation consultation. Alternatively, click the button below.